Top quality knives you can depend on. Hand forged one at a time.

Our Produts

-

Culinary

-

Outdoor

-

Utilitarian

About the Craftsman

I grew up an outdoorsman, hunting and fishing every chance I had, and working at my family’s restaurant where we serve local seafood. But I found that nothing is built to last anymore, and these two fields both require quality tools, especially knives.

With that inspiration in mind, I gathered some old tools and made my first knife. I had already discovered affordable knives were often cheaply made and quality knives were often overpriced. My first knife was not pretty, but it was functional and built to last. I decided to keep at it and eventually built my own forge, my own grinder, and I slowly ungraded my arsenal to what it is now. Knife-making is my greatest passion. It has taken me on a journey as an artist that I never anticipated. I now focus on custom Damascus blades, predominantly for the kitchen. My blades are used by collectors and professional chefs around the world. I put my heart and soul into each knife, from the aesthetic to the construction I guarantee it is the highest quality blade I can make.

Knife Care

Knives rust…

Anyone who tells you different lied to you. That’s why maintenance is crucial when owning fine cutlery. I will get into the science of the reaction that takes place, but the general idea is that steel will oxidize. While some steels are more prone to it than others, eventually they all will meet the same fate if not maintained.

Aegis Forge offers two types of knives: high carbon steel and stainless steel. High carbon steel is defined as steel having greater than .61% carbon. This carbon allows the steel to become hard and hold an edge. Generally, the higher the carbon content, the harder the steel. With this increased carbon however, comes an increase and susceptibility to corrosion. Stainless steel contains chromium for additional corrosion protection. Aegis Forge stainless knives are referred to as “super stainless,” as they offer both the hardness of high carbon steel and the corrosion resistance of stainless steel. This does not mean it will not rust. The reason many production knives do not rust is they have very little carbon in solution. This is great for a low maintenance knife, but it also means it will not hold an edge as well. I’m a nerd, but the general idea is you get what you pay for.

With modern advances in high carbon stainless steels or “super stainless,” there is little difference in performance with the added benefit of resilience to rust, but these are typically only found in a custom knife. There are, however, steps you can take to prevent corrosion altogether. First and foremost, keep knives dry. Moisture is the primary cause of rust. Directly after use, I recommend washing your knife with soap and water, and drying. After the knife is dry, wipe it down with a neutral, food-safe oil such as mineral oil. There are also specialty products such as FrogLube and AxeWax that penetrate the steel for prolonged protection. Keep the knife in its case. The felt inside will hold oil, oiling the blade for you and creating an anaerobic environment on the steel’s surface.

An additional note is that high carbon steel will patina over time. This is from normal use. Most foods are acidic, and as such, will begin to color the blade. This is normal and leads to beautiful colorations desired by most chefs. It does not affect the functionality of the knife. High carbon steel offers a slight increase in edge retention and ease in sharpening. However, if you prefer your knife to retain that brand new look, I recommend stainless steel.

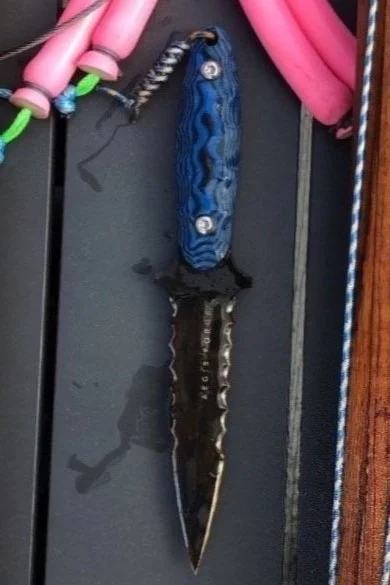

An original Bill Moran blade proudly in my collection.